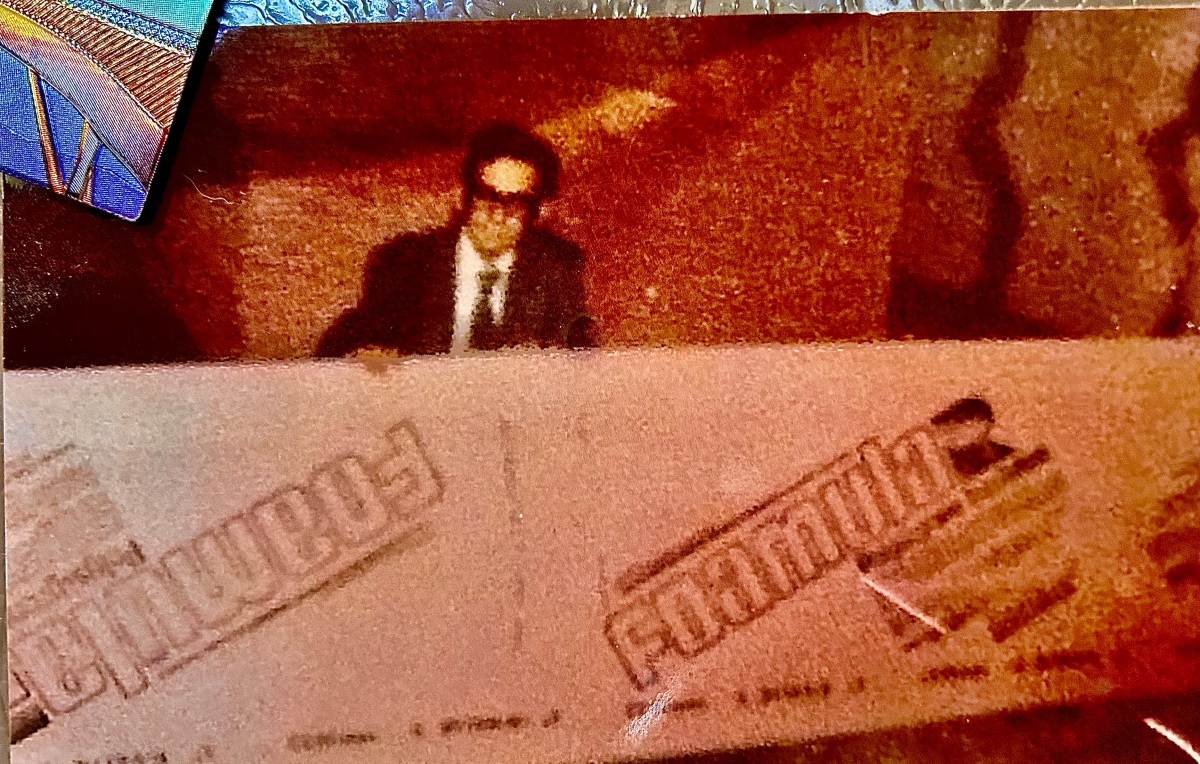

This picture of me with Mom and Dad was taken during the time they were fully engaged in building and inventing a polystyrene insulation process called Foamular. Dad acquiring several patents on the process, including on design of the extruders and dies.

By the time I was 11, my father had completed this polystyrene insulation invention. I helped out as best I could with the process. I spent my days after school gathering extruded polystyrene bead board from the lower leg of the project. Mom would cut the board samples and send me up the hill with them for density testing. We had a crude upper building office. I spent a few years of my childhood on that hillside retrieving sample board to take up to the office for testing.

My sister was taught how to gather the foam density information required. The goal being to achieve the perfect R-Factor compliance. This fine tuning process took a few years to achieve.

Dad wrote this shortly after proving his Vacuum Extrusion Process that is widely known as Owens Corning Pink “Foamular”. This was his life’s work! His invention of an extremely useful polystyrene insulation product used in the construction of commercial buildings, in homes and under roads.

My parents were movers and shakers! Brilliant people who together, helped to create a whole new insulation industry.

A family project at inception. My father scoped out and rented a hillside in Fairview, PA. He built a pilot plant with extruders he invented, and hand designed/crafted dies. I would carry the extruded test product from the lower building to the upper building for density testing. I watched my mother pull hair pins out of her hair, to fashion a clip to use on a conveyor belt. The hairpins were perfect for the task. I remember this being funny lol funny but quite ingenious as it worked perfectly. The clip she created with the Bobby pins carried extruded bead board on a conveyor belt to the lower chamber.Taking the the product through a small water pond they built for cooling and solidifying the polymer.

This took a couple of years to build and fine tune. The extruded bead board had to be a certain denisity and within specific perimeters to be just what Dad needed it to be for commercial use. Many frustrating, long, arduous days and a painstaking process to perfect but they managed to get it up and running to R Factor compliance! Mom and Dad were the pioneers of polystyrene vacuum extrusion!

Then came the two year process of proving, pitching and selling the “new invention” . My parents had exhausted all of their resources and savings in building and pitching this invention. I recall meeting with people from W.R Grace and other businesses reps. Mom would scoot down the hill all day on her butt running the tests and then play hostess in the evening to the business representatives sent by plastics companies to check out the process.

Mom would create a wonderful meal after being at the plant all day. She would feed and entertain the representatives at our humble home whenever someone came to town to observe the new invention.

I remember helping Mom make Jello Dream Pudding for dessert. Hey it was an impressive and easy dessert! She always adorned the pudding with a few thinly sliced almonds and a maraschino cherry.

By the time the process was perfected Dad had taken a 4 year hiatus from a paying job. By the time Dad was able to get this process sold, he and my Mom were scraping bottom financially. When NRM, UCI Industries, (Condec/Conplast), put together a contract that Dad reluctantly accepted. He was desperate and felt he had run out of time and money to continue holding out for a better opportunity.

Dad hired a local Erie Pennsylvania small town local, business/patent attorney. Attorney Charles Lovercheck, oversaw the business deal??? How he allowed my father to enter into such a lousy contract is beyond comprehension! Dad wasn’t a big business money man, he was a scientist. Needless to say, Dad and Mom were always incensed with the contract Dad felt he had to sign. They knew what he had invented would prove to be worth so much more…

The contract was unjust at best. Unfathomable really as it didn’t allow for royalties based on global production and sales. A cap was put on the royalties Dad should have been entitled to earn. Dad was shamed by the thought of having to settle for the stinky deal. He was tortured by this unfortunate contract later in life. Angry and strong armed by attorney Lovercheck and by attorney Scott Shafler. They ripped off my father and made bank on his global polystyrene insulation invention. Within 5 years, Owen’s Corning purchased, packaged and marketed Foamular as “Owens Corning Pink”. They used the Pink Panther trademark to sell the polystyrene insulation bead board.

As I mentioned Dad had been desperate and settled for a pittance of what he should and could have earned. My parents should have been wealthy beyond their wildest dreams…The contract that Dad entered in to was an abuse of power! Not only did my father continue to agonize over his stolen lost fortune-he died penniless and forever resentful of the contract he had signed…

To have spent his life’s work inventing such a widely known product to die a poor man seems unjustly cruel to me. When I go into Home Depot and see the product he invented on the shelves, I’m so proud of my Father! When I would see buildings under construction using “Foamular”, I would tear up with pride. These same pride filled events became a sad contentious reminder of resentment of loss for Dad.

Life lessons… #1, be careful of the contracts you sign. #2, get an attorney worth a damn not some hack of a patent attorney from Erie, PA…

Be weary of big companies who just want to roll you and, the Scott Schaflers of this world!!!

*Most importantly, don’t be desperate for a deal… I have no clue how anyone strikes a good deal that protects with integrity. Where is a “Shark Tank” guy when you need one? Awwwww!

Here is some info. I found on the web about my Dad, Arthur L. Phipps

*U.S. patent number 3,871,812 [Application Number 05/277,407] was granted by the patent office on 1975-03-18 for foam extrusion die. Invention is credited to Arthur L. Phipps.

*

Average Co-Inventor Count = 1.0

ph-index = 6

Forward Citations = 75(Granted Patents)

Company Filing History:

6 out of 7

6 out of 7

1979 1980

*Patents by Inventor Arthur L. Phipps

Arthur L. Phipps has filed for patents to protect the following inventions. This listing includes patent applications that are pending as well as patents that have already been granted by the United States Patent and Trademark Office (USPTO).